This section covers the technical standards for Displaytech monochrome LCD modules.

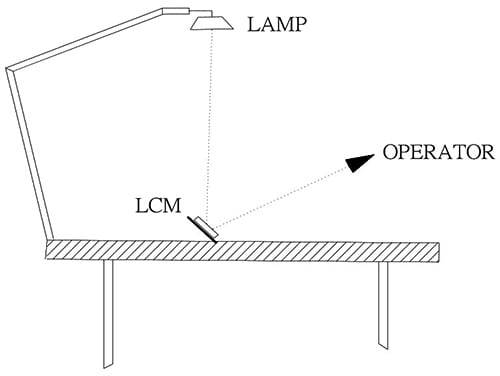

Inspection Condition

- Put the display under a lamp (20w x 2) at a distance of 100mm

- Tilt upright at a 45 degree angle by the front to inspect the LCD appearance

Image

AQL Inspection Level

Sample Method: MIL-STD-105D

Sampling Plan: Single

Major Defect: 0.65% (Major)

Minor Defect: 2.5% (Minor)

General Level: II / Normal

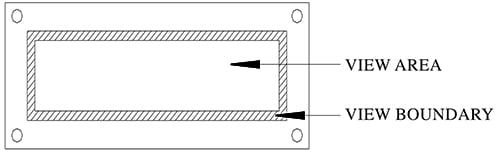

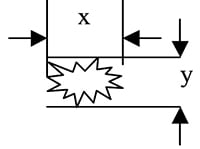

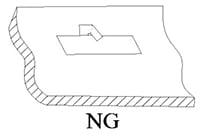

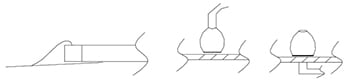

Display Area Definition

Image

LCD Inspection and Test Standard

Functional Test Standard

Acceptable Range

| Item | Inspection Standard Description | Standard | Defect Type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | LCD Has No Display | Reject | Major | ||||||

| 2 | LCM Display Does Not Change | Reject | Major | ||||||

| 3 | Display Has Wrong Pattern | Reject | Major | ||||||

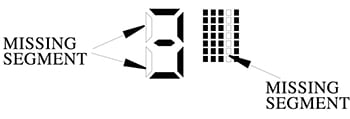

| 4 | Missing Segment on Display

Image

|

Reject | Major | ||||||

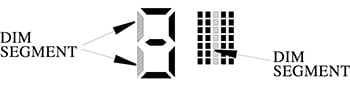

| 5 | Dim Segment on Display

Image

|

Reject | Major | ||||||

| 6 | Wrong LCD Viewing Direction | Reject | Major | ||||||

| 7 | Dim Display | See Sample | Major | ||||||

| 8 | LCD color variation | See Sample | Major | ||||||

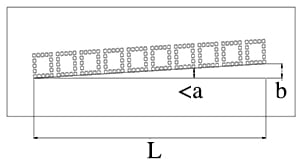

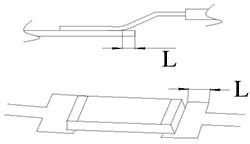

| 9 | Pattern Parallelism

Image

|

Acceptable Range | |||||||

| L | <a | b | |||||||

| ≧ 20mm | |0.43°| | ≦ 0.15mm | Accept | ||||||

| ≧ 30mm | |0.38°| | ≦ 0.2mm | |||||||

| ≧ 40mm | |0.43°| | ≦ 0.3mm | |||||||

| ≧ 50mm | |0.40°| | ≦ 0.35mm | |||||||

| ≧ 60mm | |0.43°| | ≦ 0.45mm | |||||||

| ≧ 70mm | |0.41°| | ≦ 0.50mm | |||||||

| ≧ 80mm | |0.43°| | ≦ 0.60mm | |||||||

| ≧ 90mm | |0.41°| | ≦ 0.65mm | |||||||

| ≧ 100mm | |0.43°| | ≦ 0.75mm | |||||||

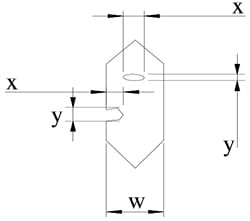

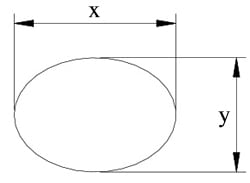

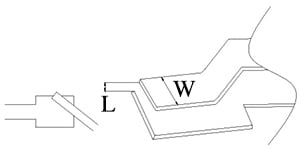

| 10 | LCD Display Pin Hole

Image

|

Standard | |||||||

| Ø = (x + y) / 2 | QTY | ||||||||

| Ø ≦ 0.25 | 1 | Accept | |||||||

| Ø > 0.25 | 1 | Accept | |||||||

| Ø < 1/4 W | 1 | Accept | |||||||

| Ø > 1/4 W | 1 | Reject | Minor | ||||||

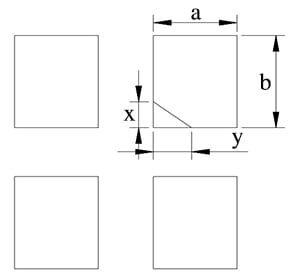

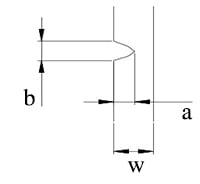

| 11 | LCD Display Broken Segment (Dots) Image

|

Standard | |||||||

| X | y | QTY | |||||||

| ≧ 1/4 b | ≧ 1/4 a | 1 | Reject | Minor | |||||

| (X or y) ≧ 0.2mm | 1 | Reject | Minor | ||||||

| ≦ 1/4 b | ≦ 1/4 a | 1 | Accept | ||||||

| ≦ 1/5 b | ≦ 1/5 a | 2 | Accept | ||||||

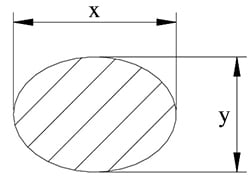

| 12 | LCD Display Black Spot or White Spot

Image

|

Ø = (x +y) / 2 | QTY | ||||||

| Ø < 0.10 | Accept | ||||||||

| 0.1 < Ø ≦ 0.20 | 2 | Accept | |||||||

| 0.20 ≦ Ø < 0.25 | 1 | Accept | |||||||

| 0.25 < Ø ≦ 0.4 | 0 | Reject | Minor | ||||||

| Ø > 0.4 | 0 | Reject | Major | ||||||

| 13 | LCD Display Excess Black Line or White Line | Black Line / White Line (L x w) mm | QTY | ||||||

| (L ≦ 1.0) × (W ≦ 0.025) | 2 | Accept | |||||||

| (1.0 < L ≦ 1.5) × (W ≦ 一 ‧ 0.025) | 1 | Accept | |||||||

| (L > 1.5) × (W ≦ 0.025) | 0 | Reject | Minor | ||||||

| (L > 2) × (W > 0.025) | 0 | Reject | Major | ||||||

| 14 | Backlight Does Not Function | Reject | Major | ||||||

| 15 | LED Does Not Function or Dim | Reject | Minor | ||||||

| 16 | Backlight Defect (dirt or scratch) | Reject | Minor | ||||||

Cosmetic Standard - LCD Appearance

| 1 | LCD Inspection Description | Standard | Defect Type | |||

|---|---|---|---|---|---|---|

| 1.1 | LCD Color Variation | See Sample | Minor | |||

| 1.2 | LCD Broken | Reject | Major | |||

| 1.3 | Wrong Polarizer of LCD | Reject | Major | |||

| 1.4 | Spot on LCD Surface | Reject | Major | |||

| 1.5 | Scratch on LCD Image

Ø = (x + y) / 2 |

Scratch = Ø | QTY | |||

| Ø < 0.1 | Except | Accept | ||||

| 0.1 ≦ Ø ≦ 0.15 | 2 | Accept | ||||

| 0.15 < Ø ≦ 0.25 | 1 | Accept | ||||

| Ø > 0.25 | 1 | Reject | Minor | |||

| 1.6 | LCD Scratch Depth Image

|

Scratch = L | Scratch = W | QTY | ||

| W ≦ 0.015 | Accept | |||||

| < 0.5 | W ≦ 0.02 | 2 | Accept | |||

| < 1.0 | W ≦ 0.03 | 1 | Accept | |||

| ≧ 1.0 | W ≧ 0.03 | 1 | Reject | Minor | ||

| 1.7 | White or Black Spot on LCD

Image

|

QTY | ||||

| Ø < 0.1 | Accept | |||||

| 0.1 ≦ Ø < 0.2 | 2 | Accept | ||||

| 0.2 ≦ Ø ≦ 0.25 | 1 | Accept | ||||

| Ø > 0.25 | 1 | Reject | Minor | |||

| Bevy point | - | Reject | Minor | |||

| 1.8 |

Black Line in LCD Image

|

(L) | (W) | QTY | ||

| L ≦ 1.0 | W ≦ 0.025 | 2 | Accept | |||

| 1.0 < 1 ≦ 1.5 | W ≦ 0.025 | 1 | Accept | |||

| 1.5 < L | W > 0.025 | 1 | Reject | Minor | ||

| 1.9 | Round Air Bubble | Size | QTY | |||

| Ø < 0.15 | 2 | Accept | ||||

| 0.15 ≦ Ø ≦ 0.25 | 1 | Accept | ||||

| Ø > 0.25 | 0 | Reject | Minor | |||

| 1.10 | Line Defect | (L) | (W) | QTY | ||

| L < 0.5 | W < 0.02 | 2 | Accept | |||

| L < 1.0 | W < 0.03 | 1 | Accept | |||

| L ≧ 1.0 | W ≧ 0.3 | 0 | Reject | Minor | ||

| 1.11 | Finger Print | Reject | Minor | |||

Cosmetic Standard - PCB / COB Appearance

| 2 | PCB/COB Specification Description | Standard | Defect Type | |||

|---|---|---|---|---|---|---|

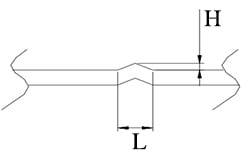

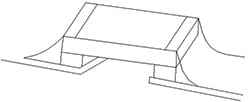

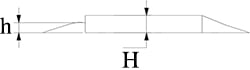

| 2.1 | PCB Deformity

Image

|

L | H | |||

| ≦ 6.0mm | ≦ 1.5mm | Accept | ||||

| > 6.0mm | ≦ 1.5mm | Reject | Minor | |||

| < 6.0mm | > 1.5mm | Reject | Minor | |||

| > 6.0mm | > 1.5mm | Reject | Minor | |||

| 2.2 | Deformity at PCB Edge, Damage Circuit | Reject | Major | |||

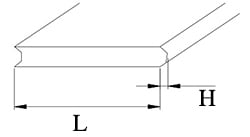

| 2.3 | Convex at PCB Edge

Image

|

L | H | |||

| ≦ 6.0mm | ≦ 1.5mm | Accept | ||||

| > 6.0mm | ≦ 1.5mm | Reject | Minor | |||

| < 6.0mm | > 1.5mm | Reject | Minor | |||

| > 6.0mm | > 1.5mm | Reject | Minor | |||

| 2.4 | Damage Excess 2 x 2mm at the PCB Corner | Reject | Minor | |||

| 2.5 | Scratch on PCB Surface | See Sample | Minor | |||

| 2.6 | Scratch on PCB Coat / Leakage Coat on PCB Surface | Reject | Major | |||

| 2.7 | Open Circuit | Reject | Major | |||

| 2.8 | PCB PTH Open | Reject | Major | |||

| 2.9 | Repair PCB PTH | QTY ≦ 2PCS | Accept | |||

| QTY ≧ 3PCS | Reject | Major | ||||

| 2.10 | Color Different from One Side to Another Side | Reject | Minor | |||

| 2.11 | Repaired Solder Mask Area | ≦ 30mm2 | Accept | |||

| ≧ 30mm2 | Reject | Minor | ||||

| 2.12 | Scratch Circuit, Damage Circuit

Image

|

a ≦ 1/2w or b < w | Accept | |||

| a > 1/2w or b > w | Reject | |||||

Cosmetic Standard - Bezel Appearance

| 3 | Bezel Specification Description | Standard | Defect Type | ||||

|---|---|---|---|---|---|---|---|

| 3.1 | Wrong Materials | Major | |||||

| 3.2 | Incorrect Dimensions | Major | |||||

| 3.3 | Bezel Broken | Major | |||||

| 3.4 | Rust on Bezel | Major | |||||

| 3.5 | Hole or Dirty on Oil Paint Surface | Size | cm2/per | ||||

| Top Surface | Ø ≦ 0.3 | 2 | Accept | ||||

| 0.3 < Ø ≦ 0.5 | 1 | Accept | |||||

| Ø > 0.5 | 0 | Reject | Minor | ||||

| Side | Ø ≦ 0.5 | 2 | Accept | ||||

| 0.5 < Ø ≦ 0.8 | 1 | Accept | |||||

| Ø > 0.8 | 0 | Reject | Minor | ||||

| 3.6 | Bezel Bow or Twist | h ≦ 0.01 mm/mm | Accept | ||||

| h > 0.01 mm/mm | Reject | Minor | |||||

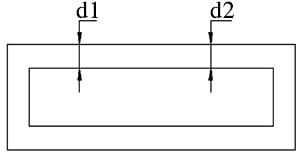

| 3.7 |

Image

|

d1 - d2 ≦ tolerance | Accept | ||||

| d1 - d2 > tolerance | Reject | Minor | |||||

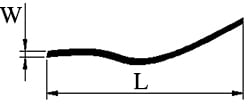

| 3.8 | Scratch on Bezel

Image

|

Face | Accept QTY | ||||

| L | W | Not Defined | See Sample | ||||

| - | W ≦ 0.15 | ||||||

| L ≦ 3 | W ≦ 0.20 | 2 | |||||

| L ≦ 2 | W ≦ 0.3 | 2 | |||||

| - | W > 0.3 | ||||||

| Side | Accept QTY | ||||||

| L | W | ||||||

| - | W ≦ 0.2 | except | See Sample | ||||

| L ≦ 3 | W ≦ 0.25 | 2 | |||||

| L ≦ 2 | W ≦ 0.3 | 2 | |||||

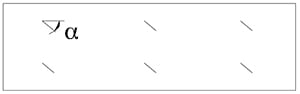

| 3.9 | Twist Angle α = 45º + 5º

Image

|

Accept | |||||

| 3.10 | Void Gap Between Bezel and PCB | Reject | Minor | ||||

| 3.11 | Bezel Clip Incorrectly

Image

|

Reject | Minor | ||||

Cosmetic Standard - Solder

| 4 | Solder Specification Description | Standard | Defect Type | ||||

|---|---|---|---|---|---|---|---|

| 4.1 | Wrong Component | Reject | Major | ||||

| 4.2 | Broken Component | Reject | Major | ||||

| 4.3 | Misalignment

Image

|

Component legs extend beyond the pad and Legs > pad distance (w) on solder area > W2 | Accept | ||||

| Component legs extend beyond the pad and Legs > pad distance (w) on solder area < W2 | Reject | Minor | |||||

| Component Offset

Image

|

Solder legs offset distance L < 1/4W | Accept | |||||

| Solder legs offset L > 1/4W | Reject | Minor | |||||

| 4.4 | Component Assembly Defect

Image

|

Reject | Minor | ||||

| 4.5 | CHIP Components Hoist ≦ 0.5mm | Accept | |||||

| 4.6 | CHIP Components Hoist > 0.5mm | Reject | Minor | ||||

| 4.7 | Components Hoist | h ≦ 2.0mm | Accept | ||||

| h > 2.0mm | Reject | Minor | |||||

| 4.8 | Switch (socket) Hoist | h ≦ 0.5mm | Accept | ||||

| h > 0.5mm | Reject | Minor | |||||

| 4.9 | Components Cold Solder or Incomplete Solder | Reject | Major | ||||

| 4.10 | Solder PAD Tilted Up, but Height (h) is less than Solder PAD thickness (a)

Image

|

Accept | |||||

| 4.11 | Excess Solder Above Components

Image

|

Reject | Minor | ||||

| 4.12 | Insufficient Solder Below Components Height or less than Diameter

Image

|

Reject | Minor | ||||

| 4.13 | Solder Area less than Soldering PAD Area by 2/3 | Reject | Minor | ||||

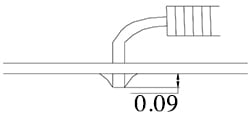

| 4.14 | Trimmed Pin Length Beyond 0.09 inch (2.3mm)

Image

|

Reject | Minor | ||||

Packaging Standard

| 5 | Packaging Specification Description | Standard | Defect Type |

|---|---|---|---|

| 5.1 | Wrong Carton Mark | Reject | Major |

| 5.2 | Carton Mark Issue | Reject | Minor |

| 5.3 | Carton Damage Extends more than 150mm | Reject | Major |

| 5.4 | Carton Damage or Scratch is more than 50mm but less than 150mm | Reject | Minor |