About IoT Device Manufacturing

IoT device manufacturing is foundational for modern connectivity and covers a range of devices and connectivity methods, with recent advancements in artificial intelligence (AI), machine learning, and cloud computing technologies leading to the emergence of a new class of electromechanical products.

Some of the key technologies enabling IoT devices include:

Microcontrollers (MCUs)

Compact, single-chip computers that handle sensing, control, and connectivity tasks in IoT devices. They range from ultra-low-power models to more capable variants that support real-time operating systems and wireless protocols.

Microprocessors (MPUs)

Found in high-performance IoT applications, microprocessors offer advanced computing capabilities, enabling complex tasks such as edge analytics, AI processing, and secure firmware updates.

Mobile Devices

Smartphones and tablets play a key role in the IoT ecosystem by serving as interfaces or hubs. Through Bluetooth or Wi-Fi, they can monitor, control, or configure connected devices with ease.

These technologies are capable of sensing, collecting, and transmitting more data across an ever-growing ecosystem of connected devices. Using embedded software that integrates with cloud-based platforms, IoT devices are able to evolve rapidly in response to changing market demands.

As a trusted innovator in electronic device manufacturing, SEACOMP works to help clients anticipate these opportunities to build better products and promote success in evolving markets. Below, you can learn more about the latest trends in IoT product development and our expert predictions for the future.

Emerging Trends in IoT Hardware Manufacturing

IoT hardware manufacturing supports multiple connectivity methods and capabilities to increase operational efficiency and personalize the user experience. Within this diverse field, there are a few key emerging trends that manufacturers should be aware of.

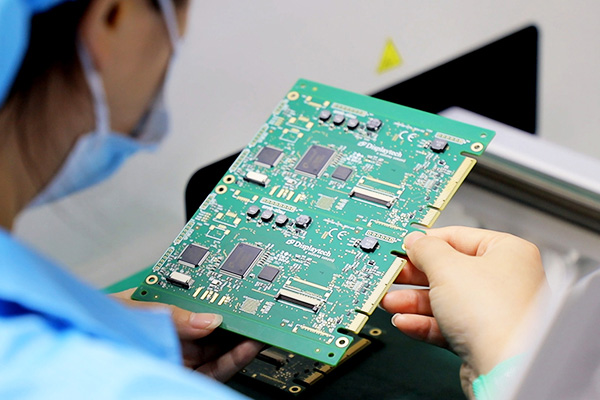

IoT Hardware Engineering

Hardware is an essential aspect of IoT technology. In addition to software and firmware, IoT devices must have the necessary physical components to interact with the physical world and perform sensing and measuring tasks. Looking to the future, engineers who can build and test hardware for real-world performance will become increasingly critical.

Data Science in IoT Device Development

Data science involves using information to test assumptions and hypotheses, identify possibilities, and make those possibilities a reality. IoT device development requires an increasingly strong, data-backed decision process to solve new problems and efficiently prototype solutions.

Industrial IoT

In industrial and manufacturing settings, IoT technology enables smarter operations, increased efficiency, and enhanced safety. Adding sensors to equipment allows for continuous performance monitoring that can predict failures before they occur. IoT-enabled predictive maintenance systems greatly reduce unplanned downtime and allow assets to be tracked in real time, optimizing inventory management. Additionally, environmental IoT sensors can be installed to monitor air quality, noise levels, and temperature, ensuring worker safety and regulatory compliance.

Challenges in Developing IoT Products

While there are an abundance of opportunities for developing new smart connected products, it's also important to be aware of potential challenges. Some of the most common pitfalls product developers can face include:

- Compliance and certification issues

- Lack of necessary technology or platform capabilities needed to develop an ecosystem

- Limited go-to-market experience

- Security by design

- Challenges securing capital, investment, and financing for smart connected products due to their longer ROI timeframes

- Vulnerabilities that may arise from a lack of testing or inadequate testing

With an experienced IoT device manufacturer, you can expertly navigate these challenges and develop a product that is not only scalable but also secure and fully integrated. The chosen manufacturing partner should take into consideration the following:

Data privacy

It's important to understand that as with any internet-connected device, when IoT sensors connect to the internet, product manufacturers are immediately vulnerable to potential cyber threats and data leaks.

Security

Security is one of the biggest threats to IoT systems. If hackers were to target an IoT environment, they could steal or modify private process information and compromise product quality. In highly regulated industries like defense or healthcare, taking proactive cybersecurity measures is paramount. IoT devices must be regularly updated to protect their security, and additional measures like connecting to private networks should be considered.

Connectivity Complexity

It's important to consider device power budgets, memory limitations, OTA update capabilities, wireless protocols, and other connectivity factors when developing a new IoT product.

Predictions for the Next Five Years

In virtually every field, the importance and capabilities of IoT devices have been rapidly growing. Some key predictions for the next five years include more connectivity advancements, the growing use of AI technology within IoT devices, more rigorous security requirements, and other developments.

Growth of Connected IoT Devices

According to researchers from Statista, by 2030, there will be over 32 billion connected IoT devices worldwide. Sectors such as healthcare, logistics, smart homes, and industrial automation are expected to see the most significant demand increases. Keeping up with this demand will require hardware developers to scale production and develop solutions tailored to new use cases.

AI in IoT (AIoT)

AI and machine learning tools are an increasingly common feature in IoT hardware, and future devices will utilize these tools to achieve faster local data processing, improved automation, and more comprehensive predictive maintenance. These changes will require advanced processors and hardware that is optimized for energy efficiency.

Connectivity Advancements

Changes in wireless standards are expanding IoT device capabilities. Advancements like satellite IoT, Wi-Fi 7, and 5G RedCap enable faster connection speeds, lower latency, and broader coverage. These changes are particularly impactful for remote and high-performance applications. For long-range, energy-efficient hardware, low-power solutions like NB-IoT and LoRaWAN will remain key.

Security and Privacy

IoT device manufacturers must be able to meet rising standards regarding security and privacy. Hardware must support secure firmware updates, unique default credentials, and built-in protections to remain compliant. In the coming years, these requirements are likely to continue evolving.

Our new 60,000 sq. ft. manufacturing facility in Mexico accommodates high-volume manufacturing projects more efficiently than ever before.

How SEACOMP Supports IoT Innovations

SEACOMP takes a holistic approach to electronics manufacturing. We use a collaborative process to bring your product to life as efficiently as possible. Through our vast expertise in IoT device manufacturing, we can seamlessly navigate various development challenges so that you can focus on innovating.

Together, let's work to build better IoT devices.

Discuss Your ProductThe Road Ahead for IoT Device Manufacturing

Today's manufacturers navigate many challenges, from skilled labor shortages to volatile supply chains and rising operational costs. Yet, these issues are also driving the demand for innovative IoT solutions. By creating purpose-built IoT products, OEMs can provide their customers with the powerful technology they need to succeed.

Whether you're looking to manufacture sensors for factory floor equipment, connect components in remote field operations, or develop tools with real-time data insights, SEACOMP is your trusted IoT device manufacturing partner.

Bring your idea to life with SEACOMP. Start a discussion about your project with our team or request a quote to get started.