An LCD display must be connected to a PCB (printed circuit board) in order to display contents on its screen. The display connector on the LCD determines how that connection is made. Here are the standard connection types for liquid crystal displays:

- Elastomer Connector

- Pin Connector

- Flex Connector

- TCP Structure

- COG Structure

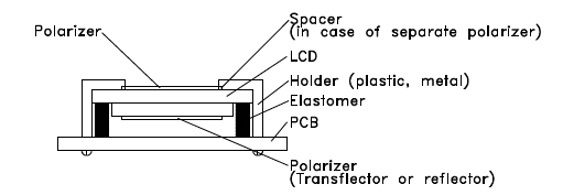

Elastomer Connector

Connection method: Mechanical compression

Structure: Alternate laminations of conductive and insulating rubber

Contact pitch: Min. 0.5mm recommended

Benefits:

- Easily assembled

- Long service life

- Suitable for fine pitch

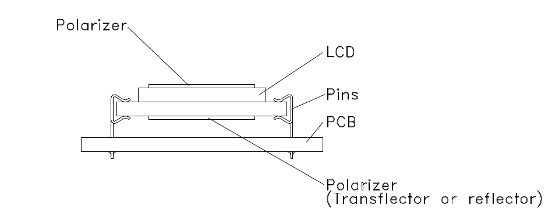

Pin Connector

Connection method: Solder

Structure: Plated metal pins

Contact Pitch: 1.5, 1.8, 2.0, 2.54 mm

Benefits:

- SMT mount possible

- Suitable small batch production

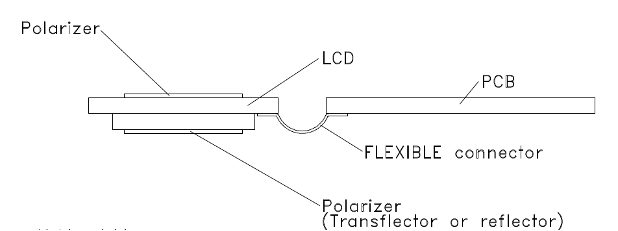

Flexible (Flex) Connector

Connection method: Heat seal (heat + pressure), solder or mechanical compression

Structure: Base film with electro-conductive traces

Contact Pitch: Heat seal type 0.28mm Min. Solder type 0.8mm Min.

Benefits:

- Light weight

- Flexible

- Thin structure

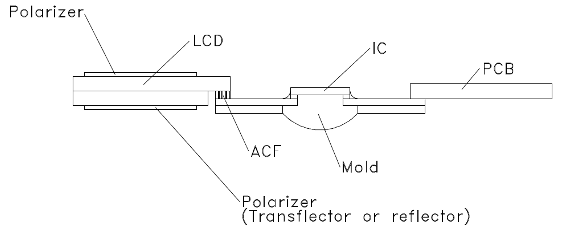

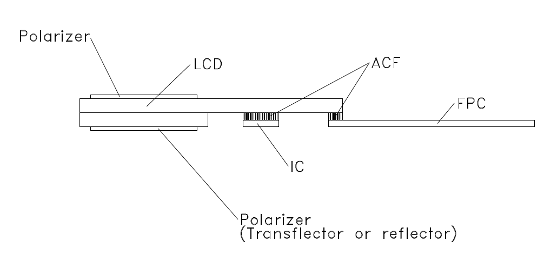

Tape Carrier Package (TCP) Structure (with driver)

Connection method: Heat and pressure fitting (ACF), soldering.

Benefits:

- High resolution display

- Thin structure

Chip on Glass (COG) Structure

Connection Method: Heat and pressure fitting (ACF), heat seal, FPC, rubber, socket or pin.

Benefits:

- High resolution display

- Saves mounting space

- Thin structure