Risk is an inherent feature of the supply chain, which is why it’s important to understand and employ best practices in your supply chain strategy to ensure continuity in sourcing, production, and fulfillment.

Sourcing: Communication is Key

Enterprise resource planning (ERP) software systems are commonplace today and serve as the digital backbone for supply chain and procurement professionals. So why are there still so many cases of late shipments even among leading organizations? The root cause can be traced to a lack of consistent communication. No matter how capable and integrated a system may be, there is nothing more reassuring than speaking with a supplier and receiving a real time business update. The supply chain is often the most dynamic feature of a business model. In many industries, particularly in electronics, component lead times are volatile and obsolescence is a concern due to frequent mergers and acquisitions, an ever-evolving technology landscape, and long design cycles.

In this world of electronics manufacturing, nothing can be said to be certain except component shortages and extended lead times. Though this is a stretch adaptation of Benjamin Franklin’s famous quote, it is an accurate assessment of two prevalent challenges posed in every electronic product’s life cycle. Fortunately, it usually takes weeks or months for electronic component shortages and extended lead times to evolve into realistic threats to the supply chain. When proactively notified, there is ample time to procure the inventory necessary to bridge a gap in supply. However, a lack of notification can result in the dreaded line down scenario. Consistent communication with the contract manufacturer (CM) is key to ensure component volatility is recognized early and actions are taken to secure safety stock. CM’s interact daily with component suppliers, distributors, and other manufacturers which provides them a high level of market intelligence and makes them among the best sources for market insights.

In this world of electronics manufacturing, nothing can be said to be certain except component shortages and extended lead times

When properly managed, component vendors offer End of Life (EOL) last time buy notices for parts which will no longer be produced. The last time buy procurement window is typically available for three to six months on average and, if missed, requires companies to either pay extremely high premiums for parts from the spot buy market or delay production runs altogether. Component life cycles should be reviewed with the CM early and often to avoid unwelcome surprises and ensure the necessary purchase orders are placed within last time buy windows.

Production: Establish a Schedule - Plan for Delays

The value of a schedule resides in its accuracy and ability to project a sequence of events. The integrity of a schedule resides in its ability to assess risk.

Product sales revenue is dependent on supply chain performance yet 90 percent of firms do not conduct a risk assessment when outsourcing production1. Component procurement, production and assembly, testing, machine maintenance, transit time, customs clearance, and holidays are just several factors which can influence the overall delivery schedule. Other macro force majeure risk factors include labor strikes, port disruptions, natural disasters, and geopolitical trade conflicts.

The following five best practices should be used when establishing a risk-conscious schedule:

-

Study the Bill of Materials (BOM)

Direct source lead times may push out with changing market conditions. It is important to investigate which distribution and spot buy procurement channels stock components on the BOM in the case of a market shortage. The BOM should also indicate which components can be substituted and list alternative options. This helps insulate against redesign when component EOL notifications are received.

-

Secure buffer stock of long lead components

Component procurement is often the longest lead activity once a purchase order (PO) is processed. Some electronic components have lead times extending out 26+ weeks. Identify a total lead time target and work backwards through the schedule to determine which long lead components need to be stocked to achieve the target.

-

Count on long transit times

The physical flow of goods is only half the logistics equation. The other half involves paperwork generation, customs clearance (if shipping internationally), and ancillary administrative tasks. For example, it may only take three weeks for a container ship to travel from Hong Kong to a west coast US port. However, this operation is more likely to take five to six weeks once the freight company is informed to book a shipment. Always build extra transit time into the schedule.

-

Factor CM holidays into the production plan

Each country has a unique set of holidays which celebrates its tradition, culture, and religion. Research which holidays may affect the supply chain and influence the production plan throughout the year. Learn how to prepare your supply chain and plan for a major holiday affecting electronic component and contract manufacturers in China.

-

Stay connected

Industry conferences, professional networking groups, and white paper articles are just a few ways to stay connected. As the saying goes, “You don’t know what you don’t know.” Dedicate time each day to consider global economic, political, and geographic forces and how they might influence supply chain operations.

Fulfillment: The Bridge to Sales

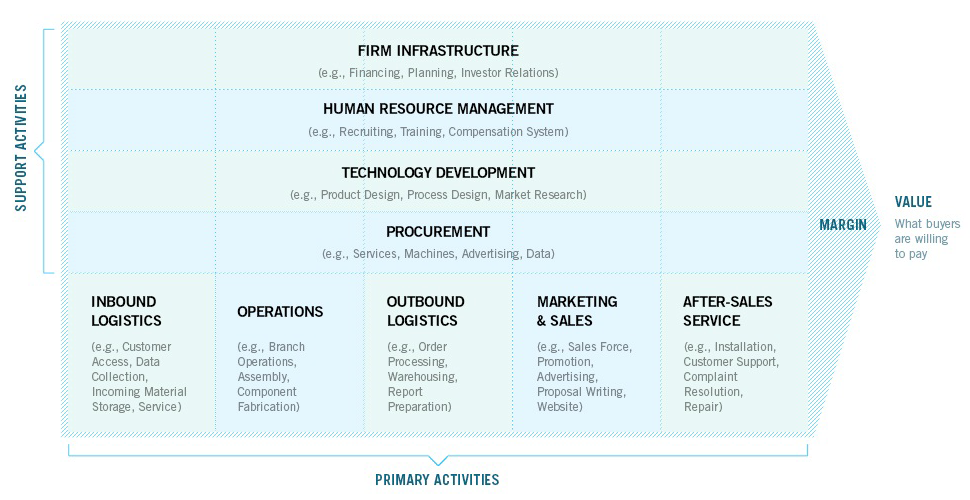

Famed academic and business strategist, Michael Porter, created the Value Chain Model which is a series of activities involved in delivering value to customers. The first three ‘Primary Activities’ from left to right at the base of the model represent supply chain operations — Inbound Logistics, Operations, and Outbound Logistics.

image via Institute For Strategy And Competitiveness - Harvard Business School

Outbound logistics is defined by the Council of Supply Chain Management of Professionals as “the process related to the movement and storage of products from the end of the production line to the end user.”2 It is when Outbound Logistics, or fulfillment, is successfully executed that sales are possible. Needless to say, fulfillment operations and strategy are very important.

Fulfillment is composed of two essential functions: warehousing and transportation. Though frameworks will vary by company and industry, there are steps with universal implications which can be taken to ensure outbound logistics operations are organized and optimized.

Warehousing

-

Identify the best location

There are costs associated with the flow of goods both into and out of the warehouse. Choosing a location which limits the overall product transit distance will reduce hard costs, minimize lead times, and help ensure prompt deliveries to customers.

-

Define services

Warehousing is traditionally viewed as a means to store product. While this is true, many warehousing organizations offer additional services including kitting, testing, and packaging of finished goods. Available storage conditions and capabilities may also vary. Making a list of required services will assist in warehouse selection and help to uncover the best option.

-

Evaluate the company culture

It is safe to presume there will be daily or weekly interaction with the warehousing team. This makes it paramount to visit a facility under consideration, observe the operations, and carefully evaluate whether the overall company culture is trustworthy and a good fit. An extra degree of due diligence should be applied since this is the last location the product will dock before reaching the end customer.

Transportation

-

Negotiate incoterms with the CM

Contract manufacturers are often setup with global warehousing operations and are willing to quote a variety of incoterms. It is advised to review and negotiate incoterms with the CM to assess the impact on product cost and internal resource allocation. This can help reduce the administrative burden of managing logistics while also offering cost savings.

-

Shop multiple carriers

Shopping multiple carriers is a surefire way to reduce operating costs

The act of shipping goods has steadily become a commodity service over the past ten years causing competition among shipping organizations to reach an all-time high. Shopping multiple carriers is a surefire way to reduce operating costs. In addition, a single carrier rarely offers competitive rates for all shipping services. It is not uncommon to use three or more shipping organizations to cover the total scope of a company’s logistics needs.

-

Get to know the account manager

Account managers for shipping companies have a surprisingly significant impact on the level of service and cost savings achievable. If and when a shipment is lost, product is damaged in transit, or a general questions needs answering, an established relationship with the account manager will lead to quicker action and better responsiveness.

In summary, consistent communication with suppliers, risk-conscious planning, and outbound logistics optimization will greatly strengthen the supply chain and help ensure on-time deliveries. The result is a stable supply chain which brings heightened control, increased customer satisfaction, and predictable sales — all of which are music to the ears.

Resources

- DITTMAN, J. PAUL, REUBEN SLONE, AND JOHN T. MENTZER. “SUPPLY CHAIN RISK: IT’S TIME TO MEASURE IT” HARVARD BUSINESS REVIEW, HARVARD BUSINESS SCHOOL PUBLISHING, 5 FEB. 2010, HTTPS://HBR.ORG/2010/02/IS-YOUR-SUPPLY-CHAIN-AT-RISK-1

- MILLER, TAN, AND MATT LIBERATORE. “OUTBOUND LOGISTICS: STRATEGIES, PERFORMANCE AND PROFITABILITY.” MATERIAL HANDLING AND LOGISTICS (MHL NEWS), MH&L, 4 OCT. 2015, WWW.MHLNEWS.COM/TRANSPORTATION-DISTRIBUTION/OUTBOUND-LOGISTICS-STRATEGIES-PERFORMANCE-AND-PROFITABILITY.